While work on the foundations and floor slab of the VAB was progressing rapidly during the latter half of 1963, there was little on-site activity on the part of the structural steel contractor. However, as the American Bridge Division began mobilizing its work force and assembling its equipment on Merritt Island, United States Steel plants throughout the country were fabricating the carbon steel plate and structural shapes required for the building's framework.17

On 4 October 1963, the Corps of Engineers advertised for bids on general construction and outfitting in the VAB area. In addition to completion of the VAB (including outfitting only high bays 1 and 3), the work covered general site preparation, roads and utility installations in the area, the construction and outfitting of the VAB utility annex and the launch control center - both good-sized buildings in their own right - and of two other support buildings, one for high-pressure-gas storage and the other for paint and chemical storage. Estimators set the price of the VAB alone at $52,000,000. The Corps of Engineers scheduled completion for 1 January 1966.18

A combine of three South Gate, California, construction-engineering companies - Morrison-Knudsen Company, Inc., Perini Corporation, and Paul Hardeman, Inc. - won the contract on 16 January 1964 with a bid of $63,366,378.19 It was not long, however, before the contract grew considerably. On 9 March the South Gate combine assumed administration of the American Bridge Division's contract for structural steel work on the VAB and the Colby Cranes contract for fabrication, installation, and testing the three large bridge cranes, as the latter two companies became subcontractors to the South Gate group. With the absorption of these two earlier contracts, the Morrison-Knudsen, Perini and Hardeman general construction and outfitting contract reached a value of $88,743,386.20 Although both American Bridge and Colby continued at their respective jobs until their completion, all VAB area brick-and-mortar construction was now under the direction of a single contractor.

The assembly building takes shape. (1) The low-bay framework, with high bays rising in the background, May 1964

With steel column sections and other structural steel arriving at the job site, erection of the framework began in January 1964 in the low bay area. By this time the original contract date for completing the structural steel (1 December 1964) had given way to a completion date of 7 March 1965. The job was a rather straightforward one although, because of the building's unique requirements, it appeared that the structure was being built wrong-side out. Because of the height of the assembly bay door openings - two on each side of the building - the horizontal stiffening structure had to be installed on the interior of the building, parallel to the transfer aisle, rather than along the exterior sides.21

The assembly building takes shape. (2) High bays to the right; the launch control center is the separate building on left, September 1964.

The assembly building takes shape. (3) In this view to the west in October 1964, the openings into the high bays are most distinct.

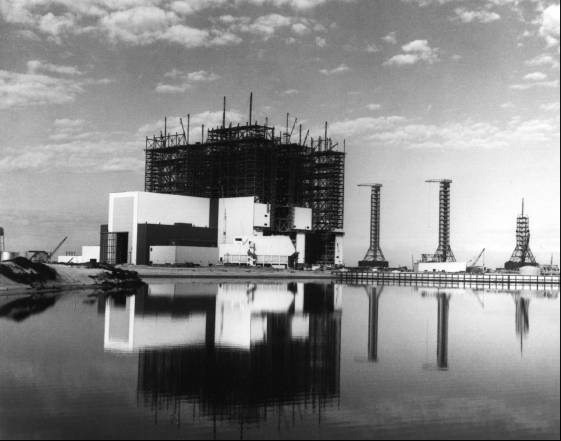

The assembly building takes shape. (4) Mobile launchers are visible to the right; the launch control center, seen end-on in the center, seems to be part of the assembly building. The view is northwest across the turning basin, January 1965.

Less than a month after steel erection began, the general construction contractor, Morrison-Knudsen, Perini and Hardeman, started work in the VAB area. After setting up a temporary office, warehouse, and concrete mixing plant on the job site, the contractors began compacting and stabilizing the crawler erection area, preparing the erection site for one mobile launcher, excavating for the crawlerway base, and excavating for the foundation floor slab of the launch control center. Contractors completed the crawler assembly area by 11 March and the mobile launcher area by 1 June.22

Meanwhile, Morrison-Knudsen, Perini and Hardeman had also begun work in February on the high-pressure-gas storage building, the road system in the VAB area, the instrumentation and communication duct banks and tunnels from the launch control center to the crawlerway, and the foundation work for the control center itself. In March work started on the water distribution and storage system, on the sewage plant and sewer system, and on the electrical distribution system. In April construction began on the VAB utility annex, on the paint and chemical storage building, and on the VAB area crawlerways.23 Thus, by the time the ironworkers of the American Bridge Division had progressed far enough with erection of the VAB framework to allow the Morrison-Knudsen, Perini and Hardeman workmen access to the building, almost all of the other construction in the general area was moving ahead. The combine started work in the northwest corner of the low bay in April.24

From this time on, employees of the two contractors worked jointly in the building, with the general construction men following closely behind the ironworkers. Joint occupancy was necessary if the building and related facilities were to be completed on schedule. Since contractors in widely scattered parts of the country worked on different parts of the total job, construction chiefs on Merritt Island had to test components regularly to see if they fitted and worked together. These so-called "fit tests" became important procedures in the early stages of construction. The installing of many pieces of vehicle-related ground support equipment - a necessity for facility checkout - had to await completion of most of the general construction.

The launch control center under construction, September 1964. The assembly building shows to the left.

The same combine of California construction-engineering companies built the launch control center as part of the VAB contract. URSAM had decided on a distinctively shaped four-story building adjoining the VAB on the southeast and connected with it by an enclosed bridge. The ground floor contained offices, cafeteria, and dispensary, the second floor telemetry and radio equipment. Firing rooms occupied the third floor, and the fourth floor had conference rooms and displays.25

The original plan called for four rectangular firing rooms, 28 by 46 meters; one was never to be equipped. When completed, the firing rooms contained similar equipment set up on four levels. The first level took up over two-thirds of the room and would ultimately contain computers and five rows of 30 consoles each. Two rows of consoles (27 in one, 25 in the other) would fill the second level. The third level would contain the consoles of the Kennedy Space Center Director and other major officials. To the left of these consoles, two diagonal rows of seats with telephones and listening devices, but no control equipment, would provide a close-up view of operations for technical experts not directly involved in the launch. On the top level, a glassed-in triangular room would give visiting dignitaries a like view. They could either watch activities in the firing room or look out the windows at the launch pads. These double-paned windows extended the full width of the rear of the firing room and contained a special heat - and shock-resistant glass. Outside, large vertical louvers, resembling huge venetian blinds, could be closed in a few moments for further protection.