While KSC officials were fighting the seemingly endless delays with the S-II stage and command module wiring, the launch team was putting Apollo 4 through the tests that would verify its flight readiness. The 456 tests in the Apollo 4 catalog fell into nine categories: electrical networks (90); measuring, fire detection, etc. (49); telemetry (27); RF and tracking (21); gyroscopes, navigation, control, and ground operations computers (86); mechanical and propulsion (146); combined systems (9); launch support equipment (13); and space vehicle (15).14

Saturn V tests, like those of the Saturn I and IB, progressed from component and subsystems tests, through systems, to combined systems or integrated tests. Hans Gruene's launch vehicle operations team began by checking out the various pieces of support equipment in the low and high bays. The "ESE qualification test, low bay" was a typical procedure. As the initial KSC checkout of the low bay's electrical support equipment, the test verified the performance of panels, consoles, cables, and the digital data acquisition system - all the electrical equipment that would be used to test the upper stages of the Saturn.15

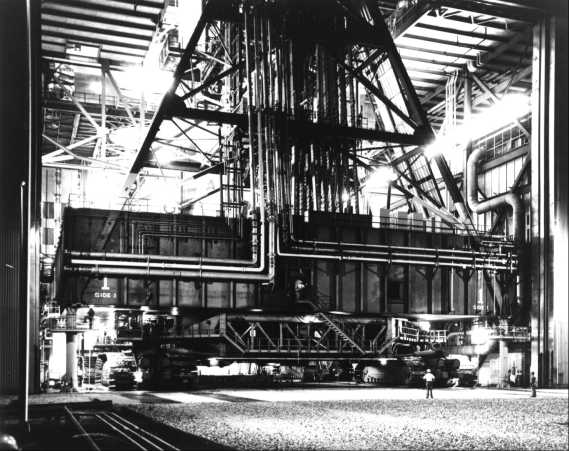

The test cells in the low bays of the assembly building.

After checkout of all the support equipment, the launch vehicle teams began testing components and subsystems within the separate stages. The checkout of the first stage was performed on the mobile launcher in a high bay, while the upper stages were tested in the low bay cells. Technicians tested valves, electrical networks, radio frequencies, measuring instruments - all the items that made up the various systems within the stages. For example, North American conducted a "pressure transducer, potentiometer type systems test" that verified the performance of the S-II's pressure transducers. (The Saturn's transducers converted such things as temperature and pressure to electrical signals.) Before conducting the test, North American checked out the second stage's digital data acquisition system and the connections to the assembly building's measurement calibration station. Then, with stage instrumentation power on, readings were taken on each pressure transducer.16

Milestones in checking out the Saturn V.

The erection of the launch vehicle in the high bay marked the first major milestone in KSC's operations and prompted a series of tests such as the "S-IC - S-II electrical mate." Three men, working eight hours, checked out the electrical interface between the two stages. Another stage test in the high bay was the "umbilical interconnect verification test, S-IVB flight stage." Through a series of measurements, a Douglas crew verified the proper plug fit and electrical continuity between power sources on the swing arm and the S-IVB networks.17

The weeks after erection were spent in system and subsystem testing and in modifying the Saturn rocket. One day of Saturn activities illustrates the extent of the launch vehicle operation:

The combined or integrated systems procedures tested vehicle functions involving several systems in one or more stages. These included the operation of the range safety command receivers and the Saturn's destruct systems, the electrical interfaces of the combined vehicle, and the transfer from external to internal power. The flight sequence test took the launch vehicle past liftoff to exercise the switch selectors that keyed the flight systems. The emergency detection system test checked out the launch vehicle's response to an abort situation. Since this system was one of the most intricate in the space vehicle, its test was one of the few automated for the Apollo 4 operation. The test employed an Apollo simulator and consisted of five parts: engine out, excessive rate (attitude), rate gyro, verification of the command module indicator, and a test of the vehicle's abort logic plan.

The integrated tests on the launch vehicle culminated with the sequence malfunction procedures and the swing-arm tests. The former was actually a series of ten tests that ran a day or more. They verified the compatibility and operation of the launch vehicle and electrical support equipment in case of a malfunction and cutoff in the last seconds of the terminal count. For example, in test 5 the launch team would simulate a malfunction in the service arms just prior to their swinging clear of the vehicles. The test would determine whether the vehicle could shut down properly. The swing arm overall test verified the operation of all Saturn and ground support equipment systems during a normal firing sequence and on into flight. The test included the actual release of the hold-down arms, umbilical ejection, and the withdrawal of the swing arms and the tail service masts. Following the simulated liftoff, the flight computer directed the various switch selectors in the Saturn stages through the operation. The exercise terminated with the engine cutoff of the S-IVB stage and the issuance of propellant dispersion system commands.19

After the spacecraft joined the stack, integrated testing continued. Several tests, such as the emergency detection system procedure, covered familiar ground but now involved a complete space vehicle. The space vehicle overall tests 1 and 2 climaxed the test operations in the assembly building. Overall test 1, popularly known as "plugs in," tested the electrical systems and some of the mechanical systems of the Apollo-Saturn, along with pertinent ground support equipment and range facilities, during a simulated normal liftoff and flight. The Saturn went through an internal power check while the spacecraft's environmental control and navigation systems were checked out. After liftoff, the test simulated stage cutoffs as they would occur in normal flight. Overall test 2, the plugs-out test, came several days later. By actually releasing the hold-down arms and the umbilical plugs, this test verified that there was no electrical interference during the umbilical disconnect. In both tests the Saturn telemetering channels operated "closed loop" over lines back to the central instrumentation facility. The spacecraft operated its radio equipment "open-loop" to the Eastern Test Range and operation and checkout building. At the close of the plugs-out test, KSC and Marshall compared data on the Saturn's operation with similar data collected during the swing arm and plugs-in tests.20

Preparing to move to the pad: the crawler-transporter under the mobile launcher and AS-501, the base of which is largely hidden by the plumbing on the launcher.

AS-501 enroute from the assembly building, left, to the pad, off right, having passed the mobile service structure in its parking position, 26 August 1967.

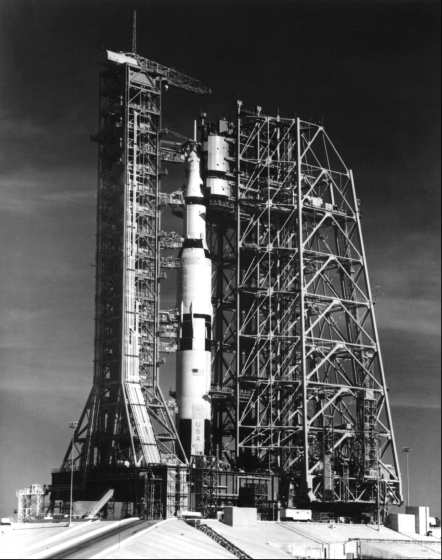

AS-501 being tested on launch pad 39A, August 1967. The mobile service structure is on the right; the access arms are extended from the mobile launcher, left.

After the rollout to the pad, integrated tests, such as the "space vehicle power-on check," verified the interface between the space vehicle and the pad facilities. The power-on test involved the ACE and RCA 110A automated checkout systems and the mobile launcher. [see chapter 16-6] A radio frequency compatibility test ensured that the pyrotechnic circuitry on the spacecraft would not be triggered by radio signals. This test was conducted in two stages, first with the mobile service structure around the Apollo, and then back at its parking site. The launch team ran another malfunction test at the pad and yet another check of the emergency detection system.21

A firing room in the launch control center; testing of AS-501 is in progress.

The flight readiness test represented one of the last major milestones. The test verified the proper operation of the space vehicle and associated ground support equipment before and after liftoff in a normal countdown, following terminal procedures as closely as possible. For this test the launch team brought the Apollo-Saturn as near as possible to its flight configuration. A minimum amount of test equipment was employed. Electrical circuits that could inadvertently damage the space vehicle were by-passed. The test conductor first ran the space vehicle through a simulated terminal count ending in a pad abort. A second run put it through tower clearance and ended with a service propulsion system abort and an earth landing for the spacecraft. After a second recycling of the count, the space vehicle flew a successful mission.22

Propellant loading tests came next, followed by the countdown demonstration test. While the flight readiness test focused on the space vehicle and its systems, countdown demonstration was intended to test the performance of the launch team and the ground support equipment. The objectives were to:

At the beginning of the simulated countdown, the spacecraft team completed all work requiring access from the mobile service structure and removed it. Then the team continued with radio checks, the closeout of the command module, a hatch leak check, and a power transfer check. The launch vehicle team performed power-on and guidance system checks, loaded cryogenics, and tested the range safety command and other radio frequencies. Finally, with the ignition systems blocked to prevent an accidental launch, the terminal sequencer took the count to T-8.9 seconds where the test ended.24

The time required to prepare for a launch varied considerably during the Apollo program. As the trial run of the Saturn V and LC-39, everyone expected troubles with AS-501. On subsequent missions, however, the checkout took longer than KSC officials expected. A major reason was the condition of the flight hardware. NASA started with the premise that stages would arrive at KSC in a nearly flight-ready condition. The prelaunch checkout would require no more than four to six weeks in the assembly building and one week on the pad. Events proved otherwise. The launch vehicle and spacecraft contractors, beset by problems, delivered stages and modules that required extensive modifications. These changes contributed in large measure to the extended launch operations.25

KSC did not achieve a standard or routine for launch operations until the Apollo 9-11 missions, each of which required over five months. The receiving, inspection, and preliminary checkout ran four to six weeks for the S-II and S-IVB stages, one to two weeks for the S-IC and the instrument unit. After the launch vehicle was erected, subsystems tests took another month. Seven to ten days of integrated tests on the Saturn were followed by the erection of the spacecraft. A month more of tests in the assembly building culminated with the space vehicle overall test 1 (plugs in). Out on the pad, three weeks of tests preceded the flight readiness test. Propellant loading tests followed two weeks later. Several days thereafter KSC began the week-long countdown demonstration test that immediately preceded launch.26