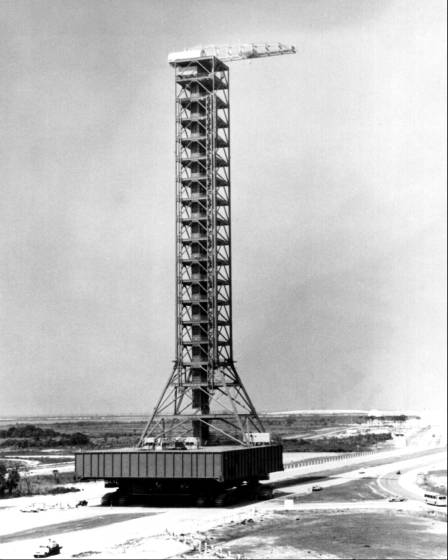

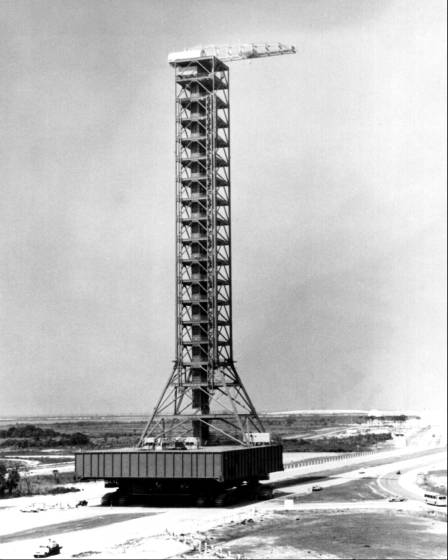

Crawler carrying a mobile launcher 24 July 1965, the day the bearing trouble was discovered.

On 24 July the crawler moved a launch umbilical tower about 1.6 kilometers to test the crawler on two short stretches of road, one surfaced with washed gravel ("Alabama River rock") and the other with crushed granite. Preliminary data on steering forces, acceleration, vibration, and strain pointed to the gravel as the better surface. While the crawler was making its run, members of the launch team found pieces of bronze and steel on the crawlerway - the significance of which was not immediately recognized. The transporter was left out on the crawlerway over the weekend because of problems with the steering hydraulic system. On the 27th more metal fragments were discovered and a thorough search disclosed pieces of bearing races, rollers, and retainers from the crawler's traction-support roller assembly. After the transporter was returned to its parking site, a check of the roller assemblies revealed that 14 of the 176 tapered roller bearings were damaged. KSC engineers attributed the failure primarily to thrust loads encountered during steering; the anti-friction support bearings, about the size of a can of orange juice concentrate, were underdesigned for loads exerted during turns. For want of a bearing, the crawler was grounded indefinitely. And for want of a crawler the site activation schedule and the entire Apollo program would be seriously delayed.26

A reexamination of Marion's design calculation indicated some other significant facts. The designers had assumed an equal load distribution on all traction support rollers; perfect thrust distribution over the entire bearing, i.e., an axial thrust equivalent to the radial load; and a coefficient of sliding friction of 0.4 (meaning it would take four million pounds of force to move a ten-million-pound object). During the early crawler runs, KSC engineers discovered an unequal load distribution on the traction support rollers. At times as many as four of the eleven rollers on one truck were bearing no load. The thrust, or side load, proved greater than expected. Finally, the crawler tests revealed that the estimated coefficient of sliding friction was far below the actual resistance experienced on the crawlerway. At a crawlerway conference on 27 June 1963, NASA engineers had insisted on a minimum design coefficient of 0.6. In the first runs on the crawlerway's macadam surface, the coefficient reached nearly 1.0.27

Troubles with the crawler had not been unforeseen. Prior to the roller bearing crisis, M. E. Haworth, Jr., chief of the KSC Procurement Division, upbraided Marion for making difficulties about the tests:

KSC has tolerated innumerable delays in the assembly, tests and checkout operations of CT-1. These delays are to the definite detriment of Apollo facilities readiness and Marion's position as to the testing operations, will, if carried out, likely cause even further delays which will have a definite and substantial dollar impact on other projects directly and indirectly connected to the crawler transporter concept. The failure of Marion to fulfill its delivery obligations is in itself costing the government substantial sums which were not contemplated.28On 14 October 1965 Haworth wrote Marion, expressing grave concern over the inactivity at the erection site consequent on a new labor dispute (the unions stayed off the job for nearly six weeks). The roof fell in on both NASA and Marion when the bearing story reached the press and television. Walter Cronkite told his evening newscast audience that the crawler was sitting on wooden blocks under the hot Florida sun, with a top Washington official stating privately that it might never work. The press and Cronkite revived the controversy over the award of the contract to Marion. Politics, they hinted, was involved; and in any case the low-bid procedure might prove penny wise and pound foolish.29

NASA and Marion could answer that the design and construction of a land vehicle expected to carry 8,000 metric tons was without precedent. Its very size, as the Corps of Engineers had pointed out, ruled out preconstruction tests of the coefficient of friction in its moving components. A more pertinent answer was to develop a new bearing, a hydraulically lubricated sleeve bearing made of Bearium B-10. KSC selected the bronze alloy after testing a half-dozen materials at Huntsville. The new design provided separate bearings for axial thrust and radial loads. KSC retained in the design the original supporting shafts that housed the bearings. Although the sleeve bearings would not reduce the amount of friction, they would eliminate the possibility of a sudden, catastrophic failure. Periodic inspection could determine the rate of wear and need for replacement. The disadvantages of the sleeve bearings-lubrication difficulties, the inability to predetermine useful life, and a need for more propulsive power because of increased friction - were acceptable. Fortunately, while the crawler design had underestimated friction, there was a considerable reserve of power. At KSC and Marion, engineers designed a new bearing system. A parallel effort modified the crawler's steering hydraulic system, almost doubling the operating pressure. At KSC, the burden of the bearing crisis fell principally on Donald Buchanan's shoulders. In Marion, Ohio, Phillip Koehring directed the redesign.30

The original design, which failed in early tests of the crawler.

The sleeve bearing, which solved the problem.

Marion reinstalled the support roller shafts in early December. A prototype of the sleeve bearing arrived on the 14th. After cooling it in dry ice and alcohol, the assembly crew placed the bearing in its housing. The fit proved satisfactory, and the remaining bearings were installed by mid-January. On 28 January 1966, the crawler transported a mobile launcher approximately 1.6 kilometers to the assembly building. Bearing measurements indicated an acceptable heat factor. Fortunately, KSC had initiated the crawler contract early enough to allow for both labor disputes and redesign of the bearing.31