Dual computers on LC-34 were largely redundant since the distance from launch vehicle to blockhouse was not great enough to attenuate analog signals. On LC-39, however, the dual arrangement was essential. The computer could not accurately process analog signals from the launch vehicle five kilometers away. In this regard, the earlier installation was intended as a testbed for the Saturn V complex. There were also important differences between the two installations. The slave computer in LC-39 was housed on the mobile launcher. Dual data links, running beneath the crawlerway, tied it to the 110A computer in the launch control center. Saturn IB operations were delayed occasionally because test engineers could not reach the slave computer's peripheral equipment during hazardous pad activities. On LC-39, magnetic tapes and other related equipment were moved back from the mobile launcher to the control center, to be available at all times. Another change involved the display systems. At LC-34, the master computer in the blockhouse processed display signals to the various consoles. LC-39 included a Sanders display system with its own digital computer. The greater size of the Saturn V dictated other changes; for example, LC-39's checkout system could issue and receive twice as many discrete signals. Perhaps the biggest difference was the increased capacity for testing. In effect there were three of everything: computers for each of the equipped firing rooms, computers in the mobile launchers for interfacing with the launch vehicles, digital data systems, and all the peripheral equipment. As a result, KSC could conduct automated tests on three Saturn V vehicles simultaneously.

As on LC-34, the 110A computers were central elements. The mobile launcher's computer tied in with the Saturn V vehicle, its peripheral equipment (line printer, card reader-punch, magnetic tapes), the launch control center computer via the data link, and the range clock system. Commands to the launch vehicle went through a discrete output system which employed triple-modular redundancy to minimize errors. Approximately 2,000 test responses returned from the Saturn V. A remote control capability in the control center allowed engineers to continue Saturn tests in the event of a computer breakdown on the mobile launcher. The RCA 110As in the control center had even more interfaces; their data channels controlled signals to and from peripheral equipment, control consoles, the dual data links to the pad, digital data systems of the launch vehicle, computer display systems, the spacecraft computer system, and the countdown clock system.13

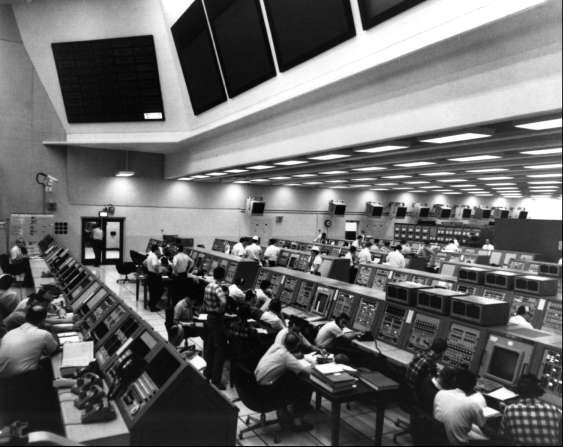

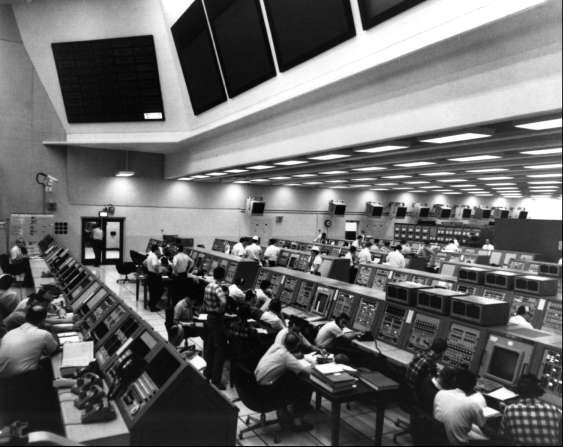

The control center was the focal point of Saturn checkout. While the original design included four firing rooms, only three were fully equipped. The various control consoles and display devices were physically grouped by stages or function. Management officials, including the launch director, test supervisor, and test conductors, occupied the first three rows. Within each stage area, test personnel were organized according to functional subsystems. Thus, in the instrument unit area were consoles for the emergency detection system, networks, guidance, stabilization, flight control, and measuring and telemetry. During prelaunch testing, approximately 400 people occupied stations in the firing room. A lesser number manned a backup control room. The test supervisor and conductors directed the operation by means of test procedures, countdown clock readouts, and an intercommunication system.14

Although equipment in a firing room varied with launch vehicle requirements, about 400 consoles were employed. Of these, approximately 100 were cathode ray tube displays. Four large overhead screens provided an additional means of displaying information. Presentations on the 2 x 3-meter translucent screens normally paralleled the test procedures, but the sequence could be altered to display data on a particular launch problem. Information from various sources appeared on the screen - telemetered data, closed-circuit and commercial television, slides, and viewgraphs. The data kept NASA managers and test conductors abreast of the vehicle status.15

An operation underway in the launch control center, firing room 1, March 1967.

An important addition to firing room equipment came after the start of Saturn V operations. While systems engineers could monitor vehicle outputs, the RCA 110A lacked the means to provide full coverage of launch vehicle measurements. Saturn engineers added an alert monitor capability to the launch vehicle display system. The equipment was first tried out in the backup firing room. In 1970 it became an integral part of the control center's display equipment. The alert monitor system - ten dual sets of cathode ray tube displays tied in with the digital data acquisition system - automatically indicated when certain measurements were out of tolerance.16